Smooth Combination: How Die Cutting Shapes Production Productivity

페이지 정보

작성자 Gino Walkley 작성일25-10-04 02:28 조회2회 댓글0건본문

The manufacturing landscape is broad, with innovations continually reshaping production landscapes. Within this dynamic environment, die cutting emerges as a crucial player, especially when it involves incorporating different materials like conductive foam, EMI shielding foam, and acrylic foam tape into uniform finished goods. This method not only speeds up production but also enhances efficiency and improves the caliber of final outputs.

Die cutting is a advanced production method used widely across multiple industries. It involves cutting, shaping, and cutting materials into precise shapes using custom tools and machinery. The technology excels in handling a wide range of materials including Thermal Conductive Silicone, Mylar sheets and Thermal Gap Pads. This versatility is vital for modern manufacturing where tailored solutions are the standard.

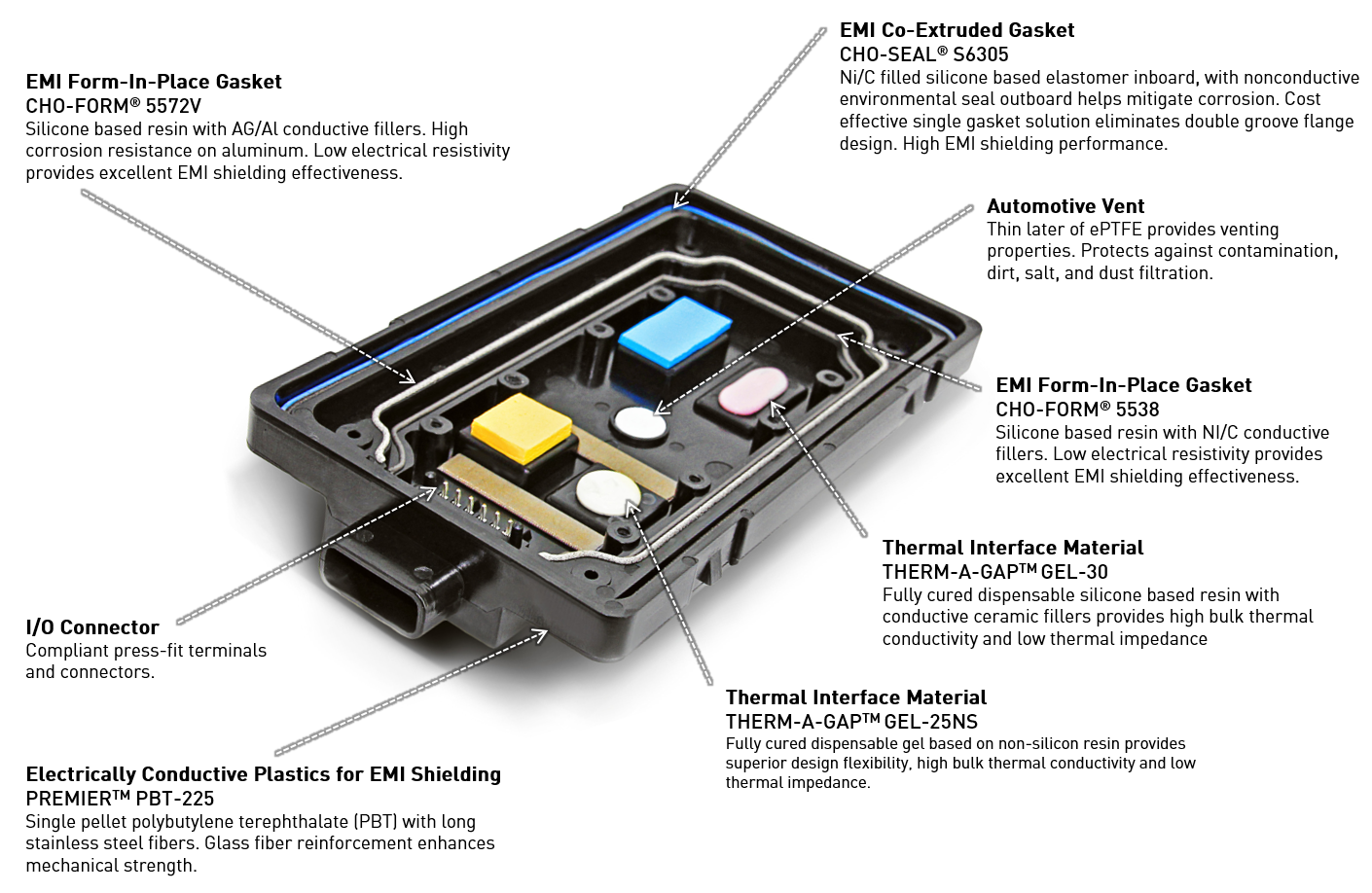

The Distinct Advantage of Die Cutting At its foundation, die cutting offers impeccability and speed, allowing for large-scale production without compromising precision. This is essential in fields like electronics, where components like EMI Gaskets, anti-static conductive foam, conductive black foam, and ESD conductive foam must meet stringent specifications to ensure functionality and safety.

Die cutting aids the incorporation of advanced materials. For instance, in the production of electronic devices, securing effective thermal management and electromagnetic interference (EMI) protection is crucial. Using die cutting, manufacturers can exactly integrate Thermal Gap Pads and EMI Shielding Foam into device designs. These materials help in releasing heat and protecting sensitive components from electrical noise, respectively.

Moreover, the application of materials such as acrylic foam tape in the automotive or construction industries highlights die cutting's role in improving traditional bonding and sealing solutions. The accurate cuts ensure that acrylic foam tapes are applied evenly, providing durable, resilient bonds necessary for structural strength and performance.

Combined with Sophistication and Sustainability One of the underappreciated aspects of die cutting is its input to sustainability. The precision associated with die cutting minimizes material waste considerably. Plus, the ability to process sustainable materials like conductive foam provides an green edge to modern manufacturing strategies.

Die cutting is not just about creating forms; it's a gateway to groundbreaking manufacturing solutions. This method integrates perfectly with other technological advancements such as automation and robotics. In the realm of disposable food packaging, for instance, providers offering services like custom 3M VHB Tapes, Protective Films, and silicone Die-Cutting serve tailored requirements while guaranteeing that products are delivered with consistent quality and sustainable practices.

Continuous Research and Development The constant exploration of materials like Mylar sheets in myriad applications is a demonstration to the adaptability and wide reach of die cutting technology. Industries are not only looking to create components but are also enhancing capabilities like transparency, flexibility, and durability of their products.

The die cutting process keeps evolving, integrating more details detailed and precise cutting techniques. These enhancements streamline production processes, elevate product quality, and reduce turnaround times, supporting industries in sustaining competitiveness in rapidly changing markets.

For those wanting to dive deeper into one of the commonly used materials in die cutting, more information on polyurethane foam's qualities, uses, and effect on the environment can be found on Wikipedia through this link: https://en.wikipedia.org/wiki/Polyurethane_foam.

Seamless, Productive, and Indispensable Die cutting's role in manufacturing transcends just shape-cutting; it’s about embracing precision, efficiency, and innovation. As industries continue to develop, the integration of various materials through specialist cutting techniques like die cutting will remain vital in defining the future of production. This process not only enables the high-speed demands of modern manufacturing but also plays a critical role in propelling product innovation, guaranteeing that every cut, notch, and crease plays a part in the main goal of seamless and productive production. Through the careful and deliberate integration of assorted materials, die cutting unequivocally drives production efficiency, making it an indispensable tool in the manufacturing landscape.

댓글목록

등록된 댓글이 없습니다.